High-Pressure Nitrogen Pumper – 10,000 PSIG / 250,000 SCFH

High-Pressure Nitrogen Pumper – 10,000 PSIG / 250,000 SCFH

Description

Performance Specifications:

The pumping system delivers an operating pressure of up to 10,000 PSIG and an impressive nitrogen flow rate of 250,000 SCFH. This makes it ideal for pipeline purging, well servicing, and high-volume nitrogen injection operations

.

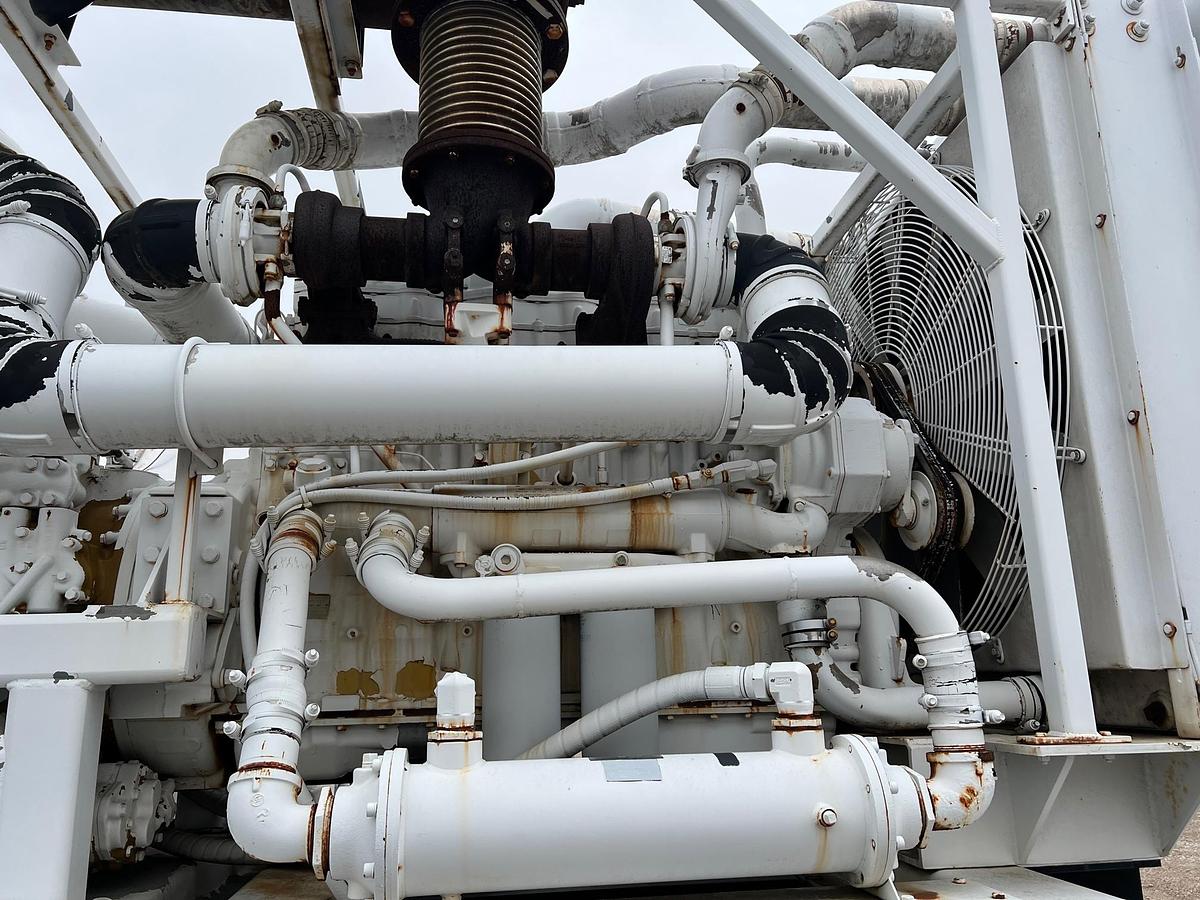

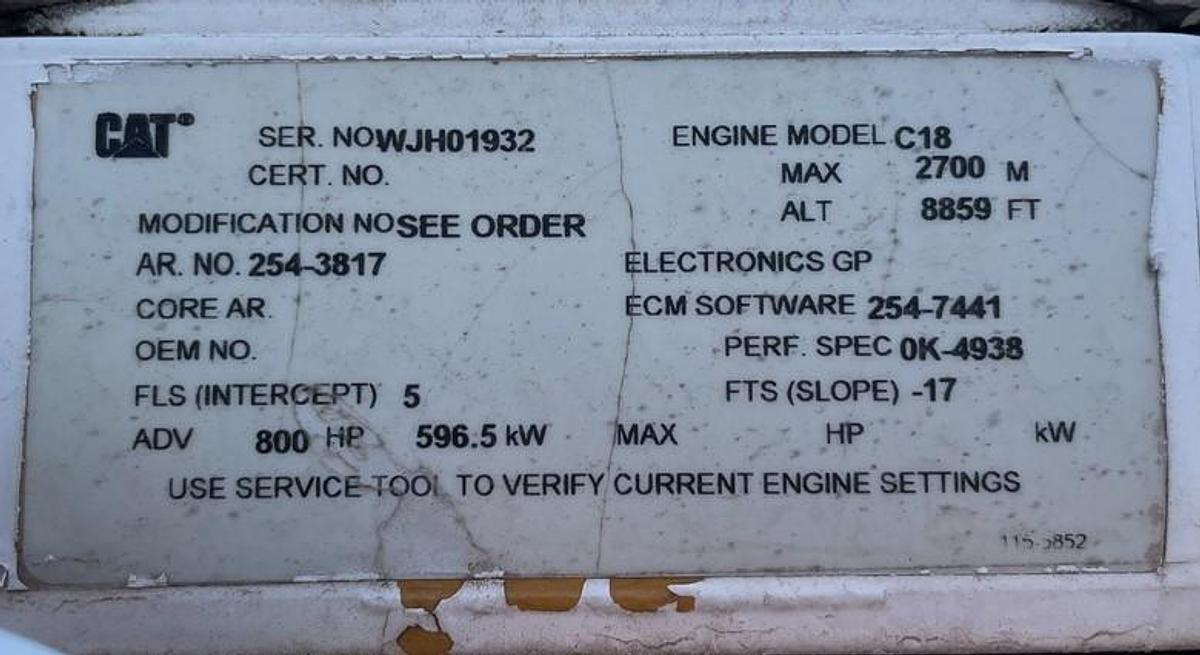

Major Components:

The unit is powered by a Detroit Diesel 8V92 main engine paired with a Fuller 1258LLR transmission for reliable torque transfer. An auxiliary Detroit Diesel 3-53 deck engine (SN 5033-7001, Spec/Part 3D 208565) supports deck operations.

The nitrogen pumping system includes a Triplex Paul Pump for consistent, high-pressure output. The onboard Zwick Model 360 burner is rated for 6,000 minutes and 360,000 operating hours, ensuring dependable thermal efficiency.

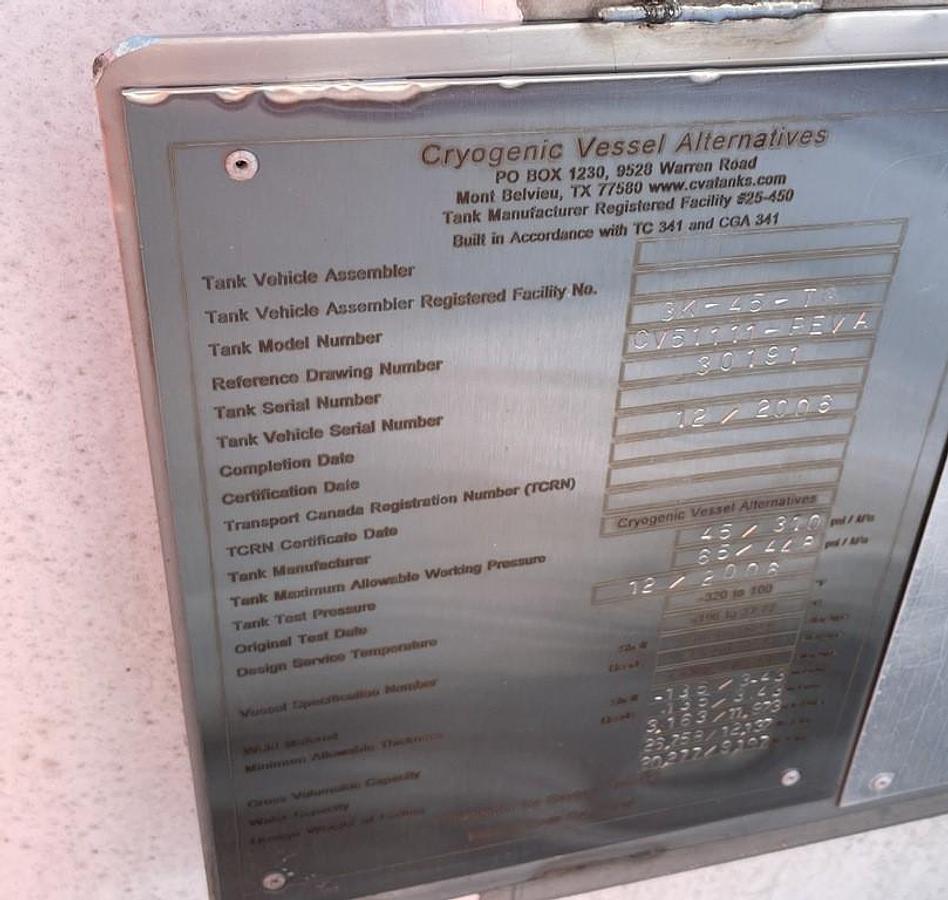

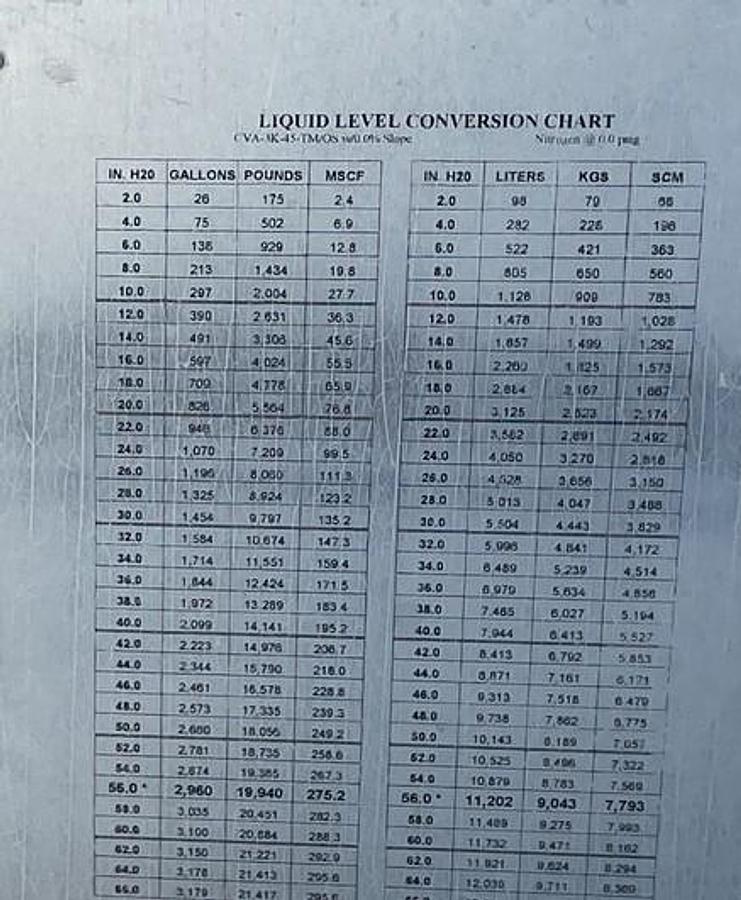

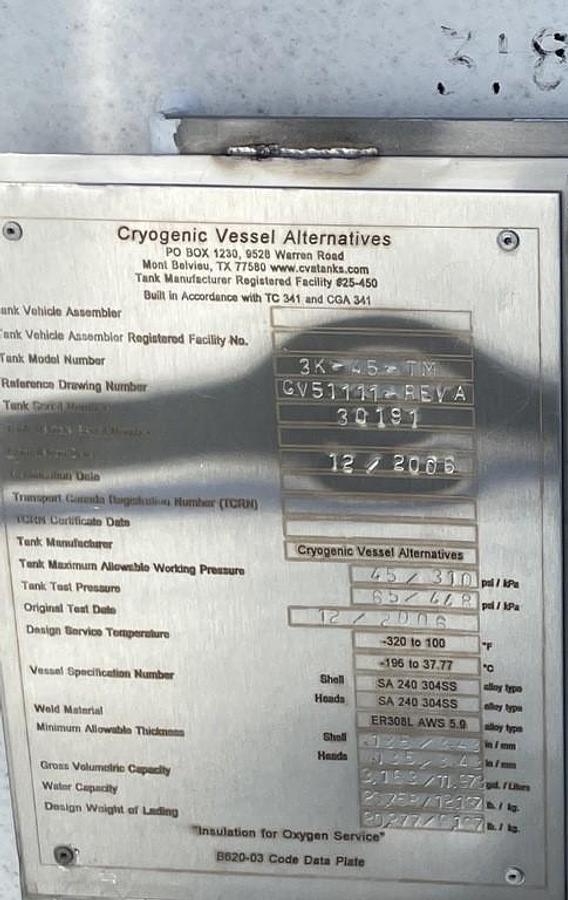

Tank & Pressure System:

The unit features a 2,000-gallon Process Engineering tank, National Board #4998, serial number C-03278. The tank is designed for durability and compliance with industrial safety standards.

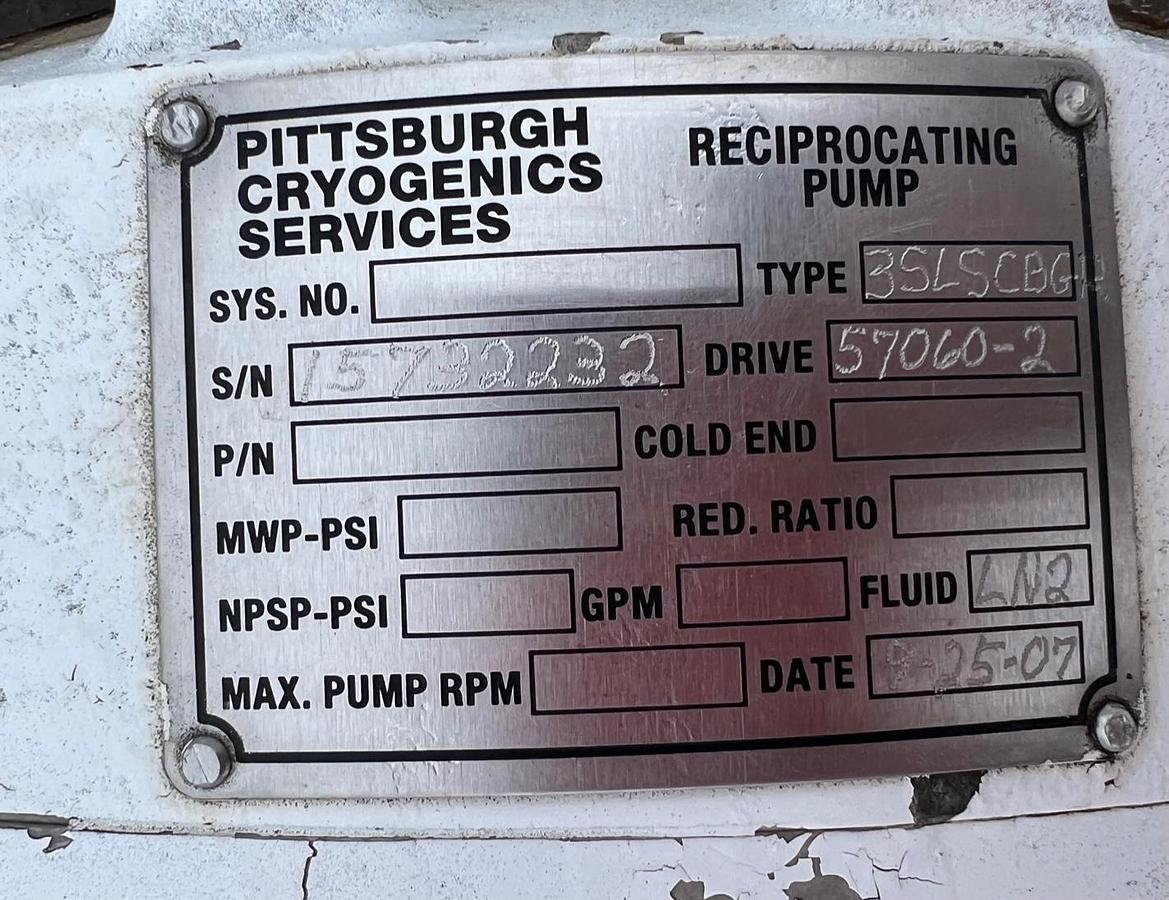

Cold End Assembly:

Equipped with a 64mm diameter SLS, STD – High Pressure Cold End Assembly rated up to 15,000 PSI (limited to 11,600 PSI on standard ACD SLS drive units per engineering constraints). Assembly includes pistons, rods, seals, and O-rings coated with specified lubricants for enhanced longevity. Torque specifications, installation tooling requirements, and piston ring gap alignments are per OEM technical documentation.

Gear & Oil System Components:

Includes a 2.35:1 parallel shaft gear reducer, precision oil inlet/discharge manifolds, bearing spacers, sleeves, adapter covers, counterbalances, and mounting flanges. Complete with an array of OEM hardware: flat and lock washers, cap screws, O-ring seals in multiple diameters, breather/filler components, eccentric spacers, and retainer rings.

Engineering & Standards Compliance:

Built and assembled in accordance with ANSI Y14.5 geometric dimensioning and tolerancing standards. Machined surfaces meet ANSI B46.1 requirements. Threading follows ANSI B1.1 for unified screw threads and ANSI B2.1 for pipe threads. Welds conform to AWS A2.4. All components are deburred, edge-finished, and designed for service accessibility.

Applications:

Pipeline pigging and purging

Oil well stimulation and cleaning

Gas field servicing

High-volume nitrogen injection

Industrial plant maintenance

Pre-Purchase Inspections:

We welcome pre-purchase inspections during normal business hours, by appointment only. If you’re planning to fly in to view or inspect the equipment in person, we are happy to arrange for that with a proper notice.

Shipping Arrangements:

We’re happy to assist with shipping logistics and can provide loading services for equipment located at our yard, for units weighing up to 15,000 lbs, when scheduled in advance.

Payment Terms:

Full payment is required before the release of any equipment. We always prefer to meet our buyers in person to discuss project needs and ensure you receive the right equipment and support for your success.

A verifiable cashier’s check is required if you're paying in person. If you plan to use a third-party shipping company, a wire transfer must be completed and cleared in full before we release the equipment. While we aim to make the transaction as smooth as possible, we take appropriate measures to protect both parties.

Contact Us:

If you have any questions, please don’t hesitate to reach out. We're happy to answer online inquiries or jump on a call to explore how any of our available equipment at GasEquipment4Sale can help support your project needs.

Specifications

| Manufacturer | HydraRig |

| Year | 1985 |

| Condition | Used |

| Stock Number | 0345-CCH-DAL |