18,000 Gallons LNG Storage Tank with Piping

18,000 Gallons LNG Storage Tank with Piping

Description

Specifications:

Model: TT18KCRYO

Configuration: Vertical

Gross Volume: 68,281 liters (18,040 US gallons)

Net Capacity: 64,867 liters (17,138 US gallons)

Design & Manufacturing Code: ASME Section VIII, Div. I (2017 Edition), Appendix 44, “U-Stamped”

Inner Vessel Material: SA 240 Type 304 Stainless Steel

Outer Vessel Material: IS 2062 Grade B or equivalent carbon steel

Maximum Allowable Working Pressure: 12.32 Kg/cm² (175 PSIG)

Design Temperature Range: -196°C to +50°C (-320.8°F to 122°F)

Insulation: High-performance vacuum with perlite fill

Inspection: Authorized Inspector certified

Operating Pressure: Maintained under vacuum

Dimensions & Weight:

Empty Weight: 23,700 kg (52,250 lbs)

Full Weight (LNG): 54,188 kg (119,462 lbs)

Outside Diameter: 3,616 mm (142.36 in)

Overall Height: 11,371 mm (447.68 in)

This Inox India Limited cryogenic liquid storage system provides high-capacity, reliable storage, pressure-building, and controlled distribution for Liquid Oxygen (LOX), Liquid Nitrogen (LIN), Liquid Argon (LAR), and Liquefied Natural Gas (LNG). Built by a globally recognized leader in cryogenic engineering, this vertical vacuum-insulated vessel is designed for maximum durability, safety, and efficiency in industrial, medical, and food-grade environments.

Construction & Design

The tank features a double-walled, vacuum-insulated design with a stainless steel inner vessel for superior cryogenic performance and a carbon steel outer shell for structural integrity. The vertical layout minimizes footprint while maximizing storage capacity. Integrated with a precision-engineered piping network and a comprehensive valve arrangement, the system ensures safe filling, withdrawal, venting, and pressure regulation.

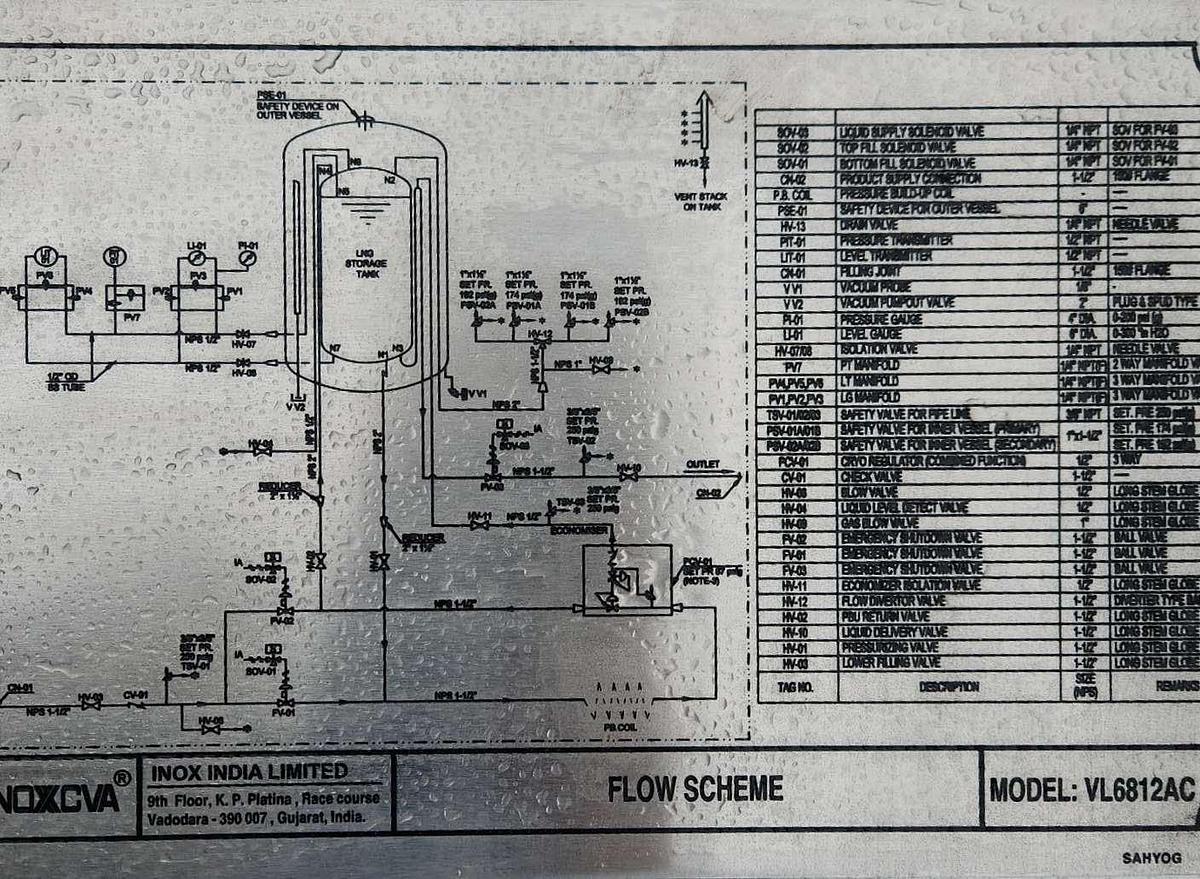

Flow Scheme & Valve Configuration

The system includes a main liquid inlet and outlet for efficient product transfer, a pressure build-up valve and coil for maintaining optimal operating pressure, multiple safety relief valves to protect against over-pressurization, a gas vent valve for controlled release of excess vapor, and a liquid withdrawal valve for direct supply to downstream applications. Evacuation and purge points are provided for safe maintenance, and instrumentation ports allow accurate pressure, temperature, and level monitoring.

Safety & Operational Benefits

Equipped with multiple redundant safety relief valves to ensure compliance with international safety standards. Designed to minimize heat ingress and reduce product loss. Features an accessible valve arrangement for efficient servicing. Compatible with high-purity applications such as medical oxygen supply and industrial gas distribution. Engineered for continuous-duty performance in demanding industrial and outdoor conditions.

Typical Applications

Medical Gas Supply: Hospitals, oxygen therapy, and emergency backup systems

Industrial Gas Supply: Welding, cutting, and manufacturing operations

Food & Beverage Processing: Freezing, chilling, and packaging applications

Electronics Manufacturing: Inert gas supply for semiconductor production

Energy Sector: LNG fueling and remote or mobile storage solutions

Pre-Purchase Inspections:

We welcome pre-purchase inspections during normal business hours, by appointment only. If you’re planning to fly in to view or inspect the equipment in person, we are happy to arrange for that with proper notice.

Shipping Arrangements:

We’re happy to assist with shipping logistics and can provide loading services for equipment located at our yard, for units weighing up to 15,000 lbs, when scheduled in advance.

Payment Terms:

Full payment is required before the release of any equipment. We always prefer to meet our buyers in person to discuss project needs and ensure you receive the right equipment and support for your success.

A verifiable cashier’s check is required if you're paying in person. If you plan to use a third-party shipping company, a wire transfer must be completed and cleared in full before we release the equipment. While we aim to make the transaction as smooth as possible, we take appropriate measures to protect both parties.

Contact Us:

If you have any questions, please don’t hesitate to reach out. We're happy to answer online inquiries or jump on a call to explore how any of our available equipment at GasEquipment4Sale can help support your project needs.

Specifications

| Manufacturer | INOXCVA |

| Model | TT18KCRYO |

| Year | 2024 |

| Condition | New |

| Stock Number | 0344-CCH-DAL |