Process Engineering 20,000 Gallon Liquid Nitrogen Cryogenic Storage Tank – 150 PSI – Horizontal Vacuum Insulated

Process Engineering 20,000 Gallon Liquid Nitrogen Cryogenic Storage Tank – 150 PSI – Horizontal Vacuum Insulated

Description

This Process Engineering 20,000 Gallon Liquid Nitrogen Cryogenic Storage Tank is a heavy-duty, horizontal bulk storage vessel engineered for long-term, high-capacity LN2 storage. Designed with a double-walled, vacuum-insulated construction, it ensures minimal product loss, reliable performance, and compliance with industry safety standards.

Specifications

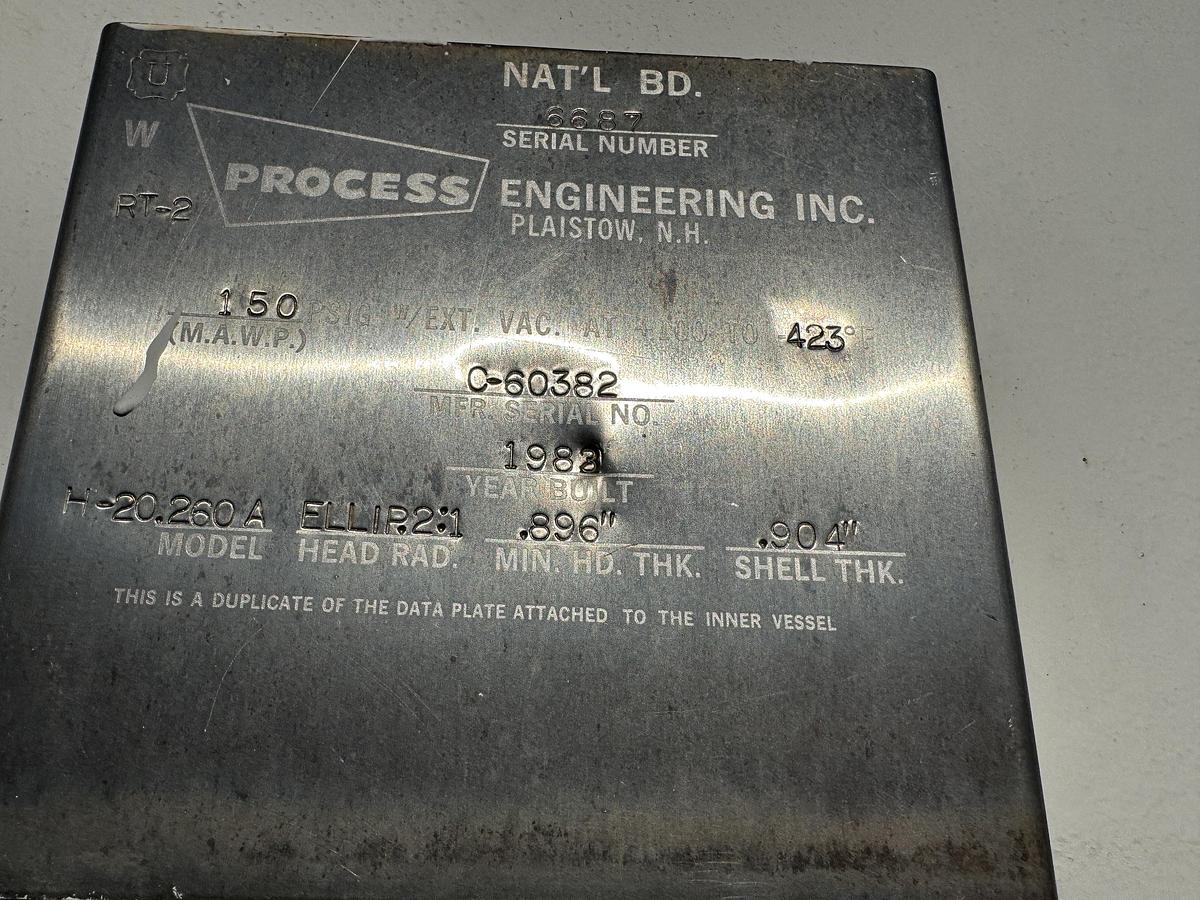

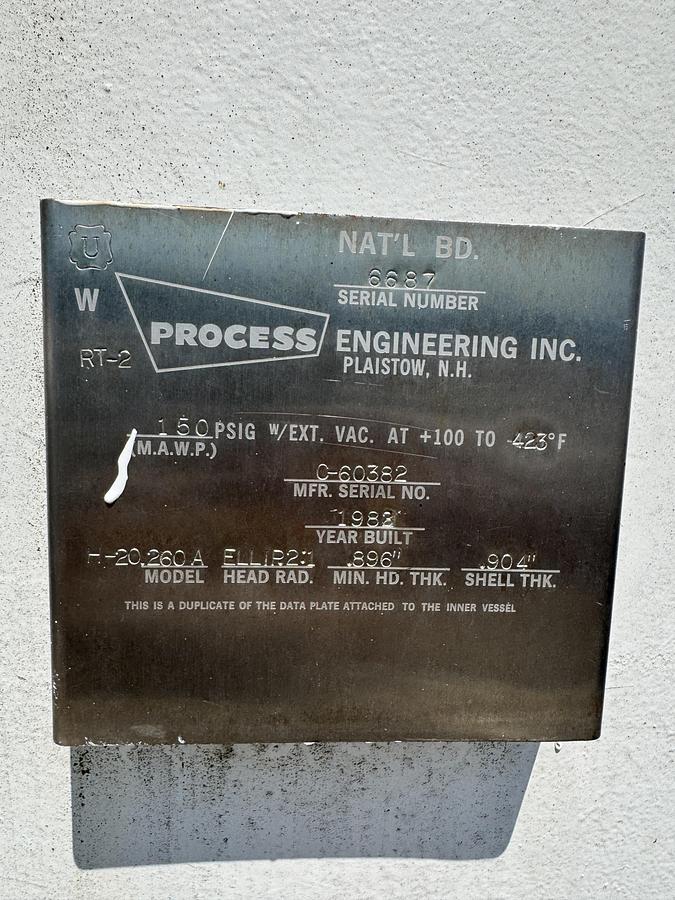

- Manufacturer: Process Engineering Inc., Plaistow, NH

- National Board Number: 6687

- Manufacturer Serial Number: C-60382

- Year Built: 1988

- Capacity: 20,000 Gallons (Liquid Nitrogen)

- Design Pressure (MAWP): 150 PSIG @ -423°F to +100°F

- Construction: Double-walled, vacuum-insulated

- Head Thickness: 0.896"

- Shell Thickness: 0.904"

- Orientation: Horizontal bulk storage tank

- Service: Cryogenic liquid nitrogen (UN 1977)

Construction & Features

- Vacuum-insulated design for maximum thermal efficiency and reduced boil-off.

- Heavy-duty steel construction with reinforced shell and head thickness for cryogenic service.

- ASME-certified pressure vessel with external vacuum jacket.

- Equipped with fill, vent, withdrawal, economizer, and safety relief valves (configurations may vary).

- Clearly marked cryogenic safety placards for LN2 storage and handling compliance.

- Built to withstand demanding industrial and commercial applications.

Applications

- Industrial nitrogen supply systems

- Food and beverage freezing and preservation

- Electronics and semiconductor manufacturing

- Metal processing and inerting systems

- Research laboratories and medical cryogenics

Pre-purchase inspections are welcomed during normal business hours upon appointment scheduled in advance. We would be happy to provide a complimentary transportation pick up from DFW Airport and back if you want to fly in and see/send someone to inspect the item in person. In addition, we can do FaceTime / Teams/Zoom calls to go over the item in person for any domestic /international procurement. Please be mindful that we are in Dallas and therefore are on the US Central Time (CT) for any communication arrangements.

Shipping Arrangements: The unit is in our yard, South of Dallas, Texas. We can assist with shipping arrangements, and when properly scheduled, we will provide loading service at no additional charge.

Payment: Payment in full FOB for our yard in South Dallas is required for equipment procurement. We prefer to see /meet the purchaser to ensure we can provide adequate after-sale support to set your project up for success. We will require a verifiable Cashier check as a payment if you are planning to come in person. We will require a wire transfer in full, with the transaction cleared in the company account before releasing the equipment to any 3rd party shipper companies. We are here to help and make this transaction as simple as possible, but we will take all necessary measures to protect ourselves and you.

Feel free to call/contact Gas Equipment 4 Sale with any questions; we will be happy to jump on the call and see if / how procuring those units can help you meet your project needs.

Specifications

| Manufacturer | Process Engineering Inc. |

| Year | 1983 |

| Condition | Used |

| Stock Number | 0353-CCH-DAL |